Microbial manufacturing is a critical component of the biopharmaceutical industry, ensuring the production of a variety of essential therapeutic proteins, vaccines, and other biologics. This article explores the solutions available for microbial manufacturing in biopharmaceuticals. We also highlight the latest advancements and best practices to ensure the efficient and high-quality production of these vital medicines. Longevity Live Paid Content

Understanding Microbial Manufacturing In Biopharmaceuticals

Microbial manufacturing involves using microorganisms such as bacteria, yeast, and fungi to produce biopharmaceuticals.

These microorganisms are engineered to express proteins and other therapeutic agents used in various medical treatments. The advantages of microbial systems include their rapid growth, ease of genetic manipulation, and ability to produce complex molecules.

How Microbial Manufacturing is applied

Microbial systems are used in the production of a wide range of biopharmaceuticals, including:

- Therapeutic Proteins: Enzymes, hormones, and other proteins used in treatments for diseases such as diabetes and growth disorders.

- Vaccines: Microbial systems are important in producing vaccines that protect against infectious diseases such as hepatitis B and human papillomavirus (HPV).

- Antibiotics: Many antibiotics are produced through microbial fermentation. This provides crucial treatments for bacterial infections.

To read more about applications of microbial manufacturing in biopharmaceuticals, go to Science Daily.

Key Solutions In Microbial Manufacturing

Optimizing Strain Development

Strain development is the foundation of microbial manufacturing. This involves the selection and genetic modification of microorganisms to produce the desired biopharmaceutical product.

Advances in genetic engineering and synthetic biology have significantly improved the ability to create microbial strains with enhanced productivity and stability.

Gene Editing

Innovative techniques such as CRISPR-Cas9 gene editing allow for precise modifications to microbial genomes. This enables the development of strains that can produce higher yields of biopharmaceuticals with improved quality.

Also, the use of synthetic biology enables the design of microorganisms with optimized metabolic pathways, increasing the efficiency of production processes.

Enhancing Fermentation Processes

Fermentation is a critical step in microbial manufacturing, where microorganisms are cultured in controlled environments to produce biopharmaceuticals. Optimizing fermentation processes involves carefully regulating conditions such as temperature, pH, and nutrient availability to maximize microbial growth and productivity.

Recent advancements in fermentation technology, such as high-density fermentation and perfusion bioreactors, allow for the cultivation of microorganisms at much higher cell densities than traditional methods.

These technologies increase the yield of biopharmaceutical products and reduce production costs, This makes microbial manufacturing more efficient and scalable.

If you want to learn more about fermentation technology, check out TechCrunch.

Innovative Downstream Processing

Downstream processing involves the purification and formulation of biopharmaceuticals after fermentation. This stage is critical for ensuring the purity, potency, and stability of the final product. Advances in downstream processing technologies are enhancing the efficiency and effectiveness of these processes.

Continuous chromatography is a breakthrough in downstream processing that allows for the continuous flow of products and reagents through the purification system.

This method increases the throughput and reduces the time required for purification, to ensure that high-purity biopharmaceuticals are produced more efficiently.

Single-use technologies are becoming increasingly popular in downstream processing due to their flexibility and cost-effectiveness. These systems use disposable components, such as filtration units and tubing, which are replaced after each production run.

Single-use technologies reduce the risk of cross-contamination and improve the overall efficiency of biopharmaceutical production.

Ensuring Quality And Compliance

Advanced Quality Control Techniques

Advanced quality control techniques are employed to ensure that biopharmaceutical products meet stringent regulatory requirements and are safe for patient use. It’s essential that at all times manufacturers maintain high standards of quality in microbial manufacturing

Real-time monitoring and control systems are used to continuously track critical process parameters during microbial manufacturing.

These systems allow for immediate adjustments to be made if any deviations are detected. This will ensure that the production process remains within the desired specifications.

High-throughput screening technologies are also used to analyze large numbers of samples quickly. In this way, comprehensive data on the quality of biopharmaceutical products can be provided.

Regulatory Compliance

Regulatory compliance is a significant challenge in microbial manufacturing, given the complexity of biopharmaceuticals and the stringent standards imposed by regulatory bodies. Companies must adhere to Good Manufacturing Practices (GMP) and other regulatory requirements to ensure that their products are safe and effective.

By investing in advanced compliance tools and systems, companies can streamline the regulatory approval process and minimize the risk of delays. This commitment to compliance is essential for building trust with regulatory bodies and ensuring that biopharmaceuticals are produced to the highest standards.

The Role Of CDMOs In Microbial Manufacturing

Supporting Biopharmaceutical Production

Contract Development and Manufacturing Organizations (CDMOs) play a vital role in the biopharmaceutical industry by providing specialized expertise and infrastructure for microbial manufacturing.

CDMOs offer a range of services, including process development, scale-up, and large-scale production, allowing biopharmaceutical companies to leverage their capabilities and bring new products to market more quickly.

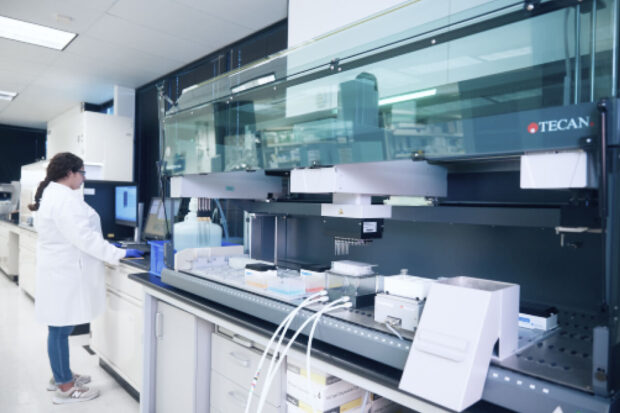

One notable CDMO specializing in microbial manufacturing is Tanvex CDMO. They provide comprehensive solutions for the development and production of microbial-derived biopharmaceuticals. Their state-of-the-art facilities and advanced technologies support the entire lifecycle of biopharmaceutical products, from early-stage development to commercial production.

By partnering with CDMOs, biopharmaceutical companies can access the expertise and resources needed to efficiently develop and produce high-quality biopharmaceuticals.

Collaboration is crucial for meeting the growing demand for microbial-derived therapies and ensuring the timely delivery of these important medicines to patients.

Ensuring Product Quality And Safety

CDMOs also play a critical role in ensuring the quality and safety of biopharmaceutical products. They adhere to strict regulatory standards and employ advanced quality control techniques to monitor every stage of the production process. This ensures that biopharmaceuticals meet the required safety and efficacy standards and are suitable for patient use.

By partnering with CDMOs, biopharmaceutical companies can ensure that their products are produced to the highest standards, reducing the risk of regulatory issues and ensuring patient safety. This collaboration is essential for maintaining the integrity and quality of microbial-derived biopharmaceuticals.

Challenges And Future Directions

Addressing Technical Challenges

Microbial manufacturing presents several technical challenges, including the need to optimize microbial strains, improve fermentation processes, and enhance downstream processing.

Ongoing research and development are focused on addressing these challenges and developing new technologies that improve the efficiency and scalability of microbial manufacturing.

Innovations such as automated process control systems and advanced analytical techniques are being developed to enhance the precision and reliability of microbial manufacturing processes. These advancements are essential for ensuring the consistent production of high-quality biopharmaceuticals. Also for meeting the growing demand for these therapies.

Expanding Innovative, New Applications Of Microbial Manufacturing

The future of microbial manufacturing holds exciting possibilities for expanding the range of biopharmaceuticals that can be produced using microbial systems. Research is ongoing to develop new microbial strains that can produce more complex and diverse biopharmaceutical products. This includes personalized medicines and novel therapeutic agents.

Endnote

It is exciting to see advancements in synthetic biology and genetic engineering, which are opening new avenues for microbial manufacturing. This is enabling the development of microorganisms with enhanced capabilities and improved production efficiency.

Clearly, these innovations have the potential to transform the biopharmaceutical industry and provide new treatment options for patients with a wide range of medical conditions.

Main photo and in content credit; TanvexCDMO

![women [longevity live]](https://longevitylive.com/wp-content/uploads/2020/01/photo-of-women-walking-down-the-street-1116984-100x100.jpg)